30.05.2024

Author: Soledad Francke | Aquaculture Product Marketing Manager at IMV Technologies

Aligned with the principles of the Blue Revolution concept, the FAO underscores the imperative for robust advancements in aquaculture characterized by innovation, sustainability, efficient management practices, technology transfer, and genetic enhancement initiatives, required to reach the 200 Million tons coming from aquaculture by 2030.

In laying the groundwork for the secure transfer of genetic material, the World Organization for Animal Health (WOAH) is engaged in formulating a new legislation, designed to mitigate the risks of disease transmission across international borders.

Central to this legislative framework is the redefinition of the concept of Disease Free Compartments and Collection Centers, emphasizing environments where gametes are obtained under the strictest biosafety protocols.

Among the array of options for genetic material transfer, the utilization of cryopreserved semen emerges as the most promising alternative. This method affords the flexibility for quarantine and various analyses, accommodating potential delays without compromising semen quality.

Notably, historical parallels can be drawn to the 1970s, when similar concerns were raised regarding the transfer of bovine semen with the dual objectives of addressing global food insecurity and disseminating genetic advancements to regions with pressing agricultural needs. Subsequently, comprehensive standards were established governing the production, packaging, and storage of semen, alongside the formulation of an international regulatory framework.

Presently, there exist over 400 bovine insemination centers worldwide, collectively yielding over 500 million straws annually containing semen sourced from elite genetic lineages. Established protocols encompass logistics, traceability measures, and adherence to both international and local regulations. Through a simple code scan, producers access to comprehensive health data pertaining to the source bull, while catalogs provide detailed information on individual bulls or genetic lineages, facilitating predictive breeding strategies.

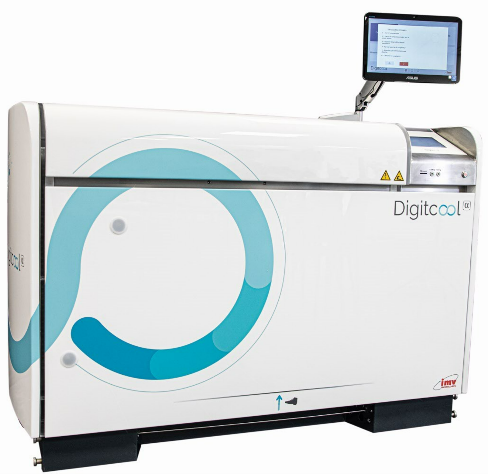

The production of frozen salmonid semen is traversing a similar trajectory. Cryolab have emerged as fully automated facilities capable of producing approximately 15 thousand straws daily, sufficient to fertilize 5 million eggs. This advancement suggests the potential to significantly diminish the requisite number of male specimens in each generation with the subsequent production cost reduction.

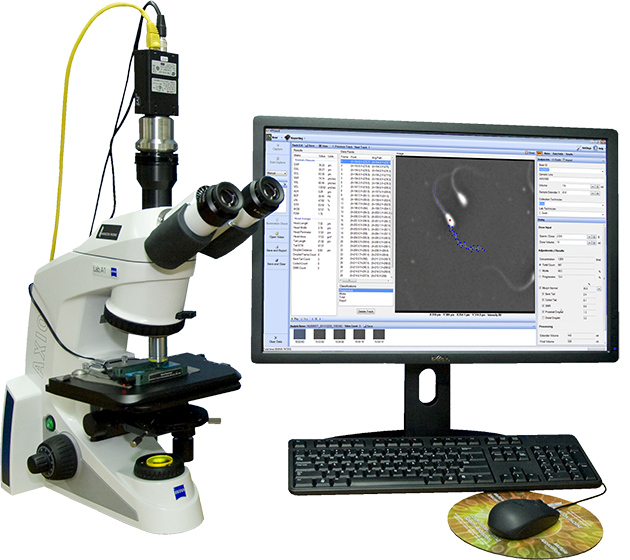

Cryolabs operate as highly automated laboratories, overseeing all facets from semen quality assessment to straw storage. Equipment configurations are tailored to accommodate daily production quotas, male collection rates, and short-term volume projections.

Predominantly, the primary cost associated with utilizing frozen semen lies in the procurement of liquid nitrogen requisite for straw storage maintenance and replenishment. Therefore, optimizing storage space within each storage tank is paramount. The utilization of straws, as opposed to alternative containers or tubes, yields nitrogen cost savings of up to 80% compared to freezing packs or other technologies.

Given the manifold advantages outlined above, stakeholders are encouraged to conduct a comprehensive cost analysis pertaining to freezing procedures and contemplate the installation of a cryolab facility on their premises. Ownership of such a laboratory offers tangible benefits, including: